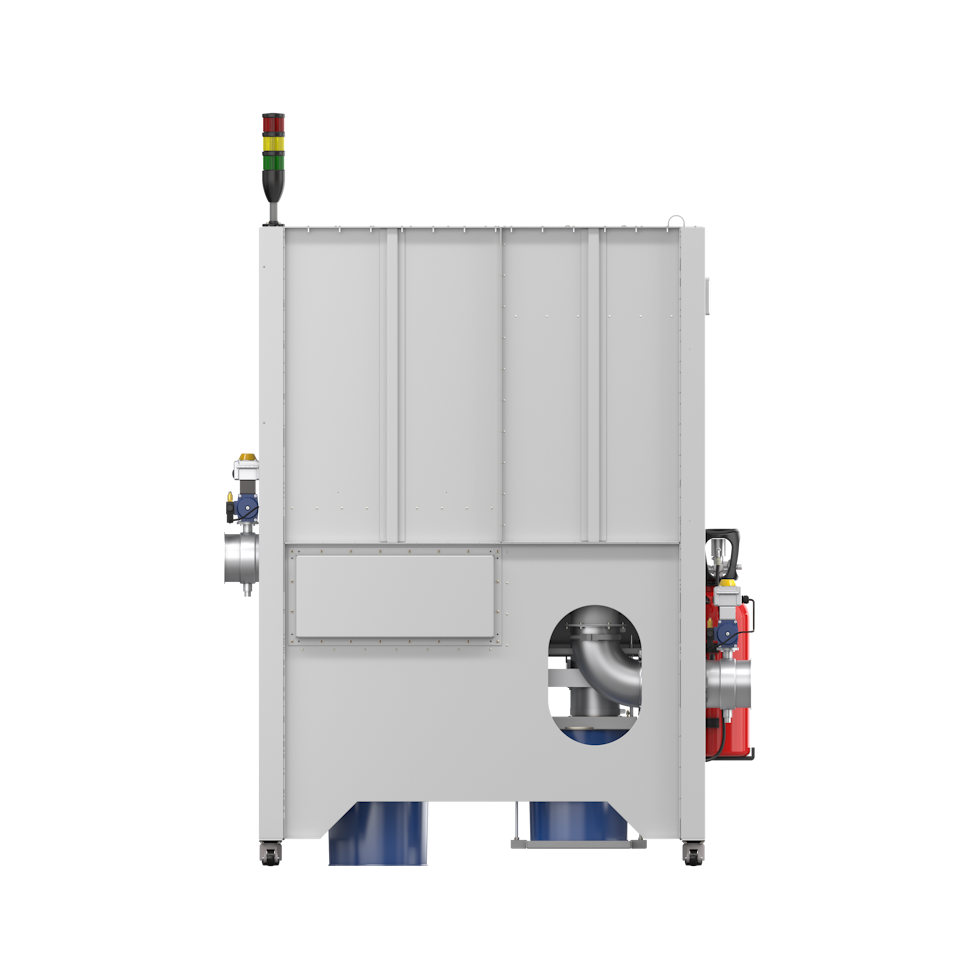

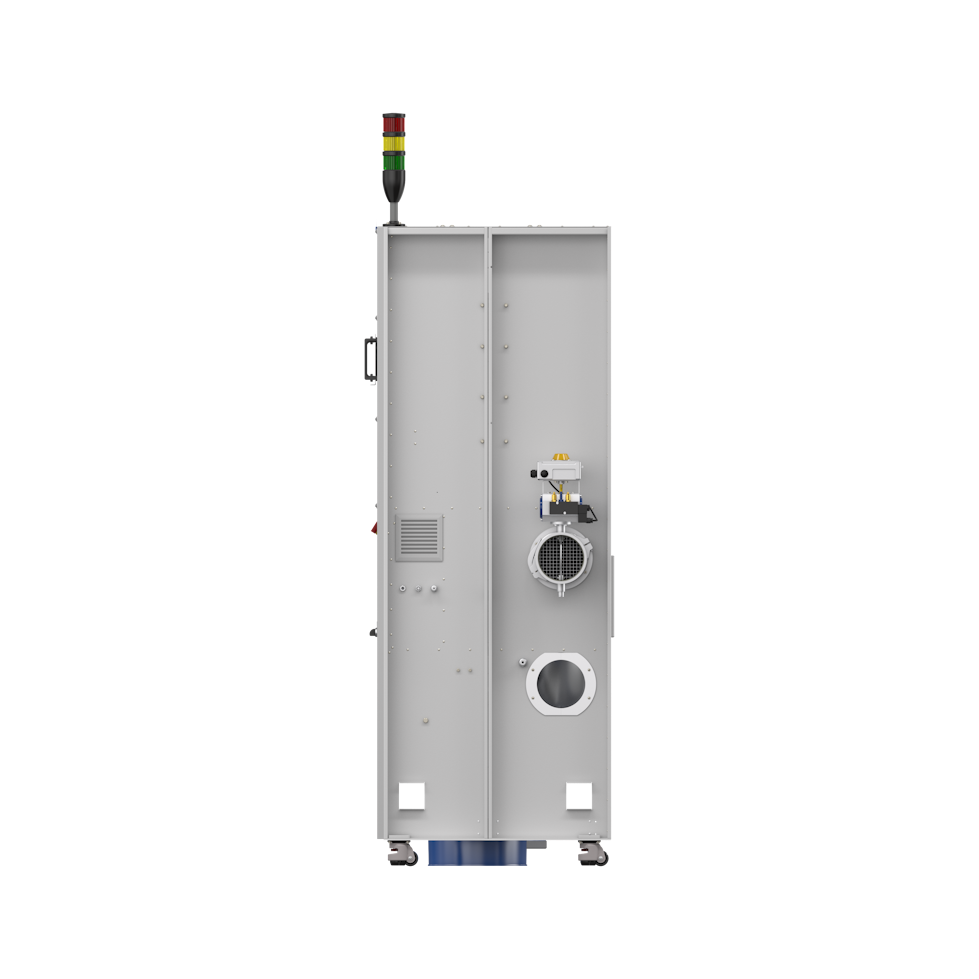

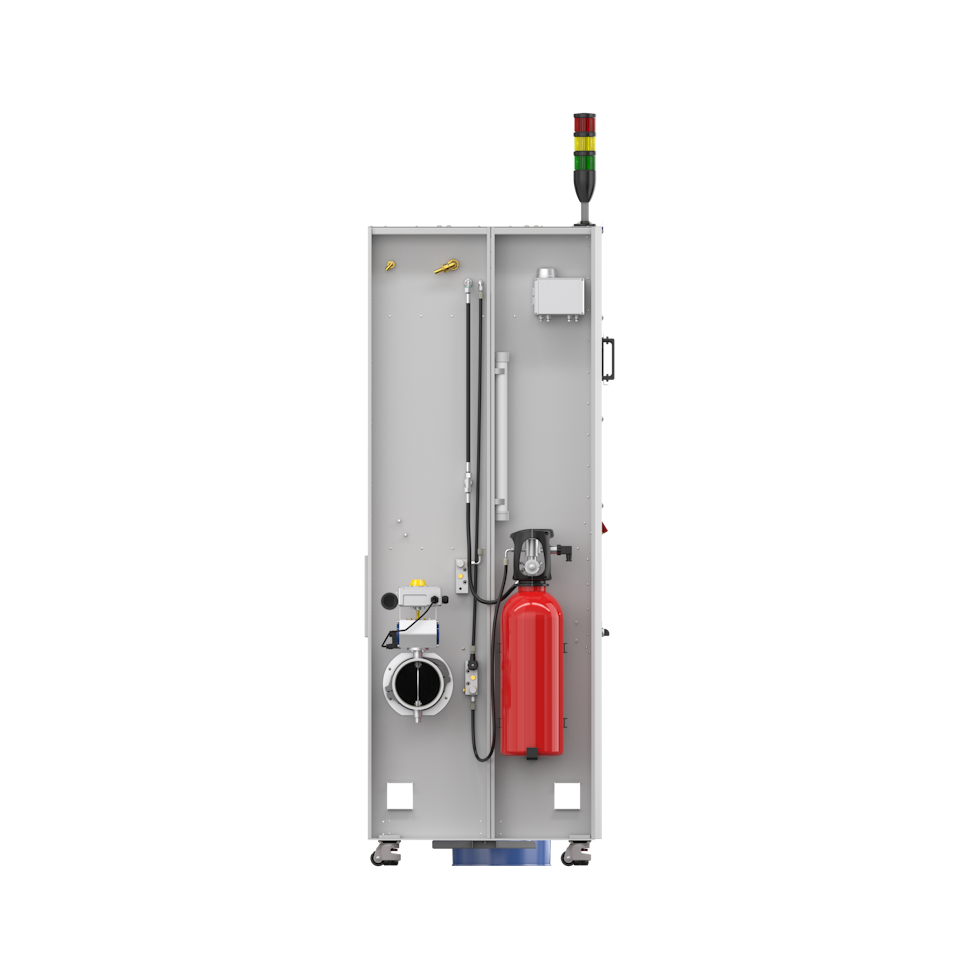

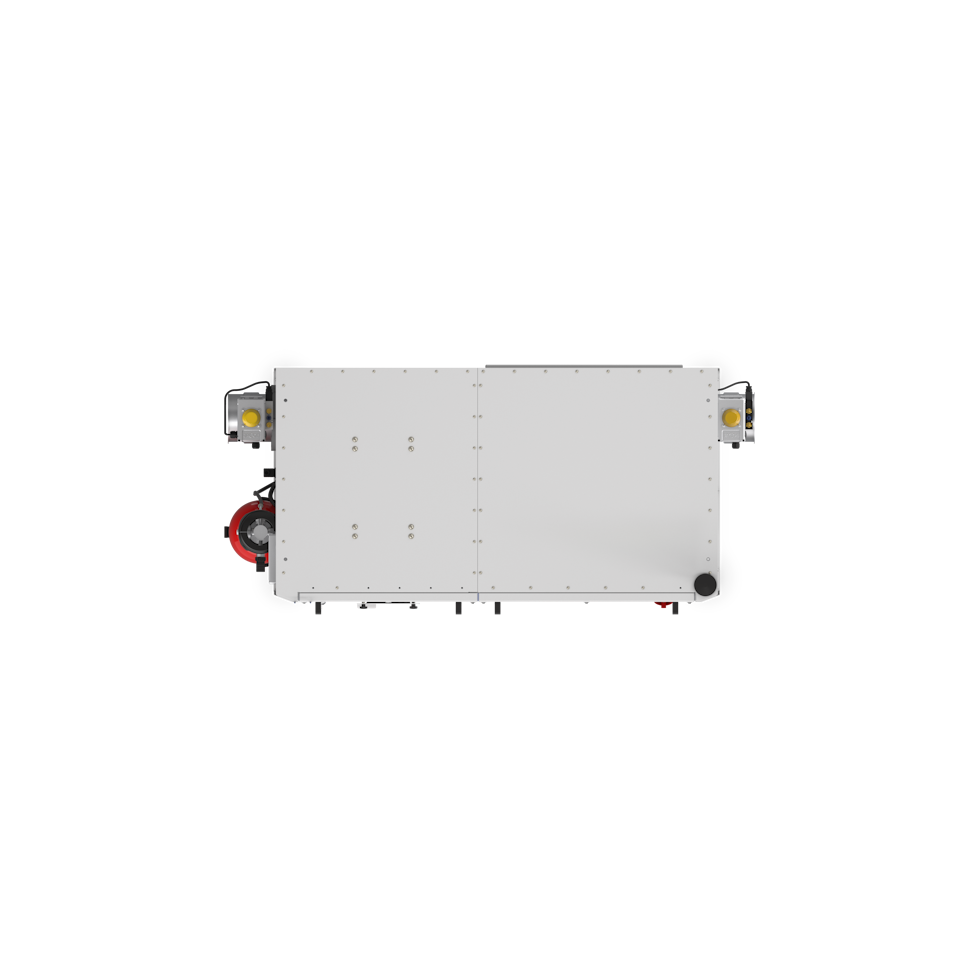

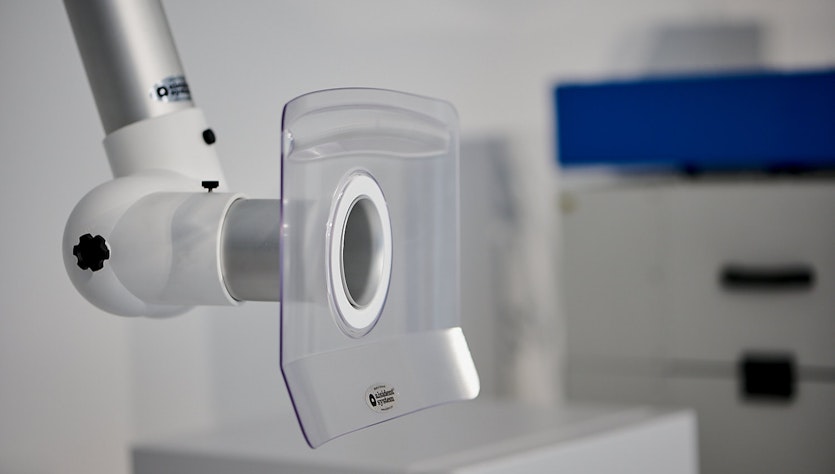

LAS 800 – Modular & Universal Laser Fume Extractor

Product Details

Application Fields

Laser welding, laser engraving, laser cutting

Laser structuring, laser ablation, laser marking, laser printing, etc.

Utilization with changing materials to be processed

Features

Stationary extraction unit

Combination of cartridge filter system with optional storage filters

Powder coated, robust steel housing

Control elements on the front panel

Digital device control, control unit integrated

Digital device display

Volume flow control

Particle filter clogging

Operating hours counter

Interface for external control

Copper baffle plate for optimal inflow conditions, coarse particle separation and to prevent impact sparks

Options

Casters with stands

Butterfly valve air inlet and outlet

Gate valve for dust collector

Exhaust air silencer

BUS communication PROFINET

Pressure sensor, level sensor

Spark separator, spark detection

Extinguishing system

Signal light

Temperature monitoring

Filter aid addition

HEPA filter H14

Automatic switch-off H14

Activated carbon 16 kg or 32 kg

Chemisorption filter 50% 21 kg or 42 kg

Chemisorption filter 100% 26 kg or 52 kg

Technical specifications

| Device version | LAS 800 HD.60 |

|---|---|

| Max. flow rate in m³/h | 1620 |

| Max. flow rate in cfm | 953 |

| Max. vacuum in Pa | 8500 |

| Max. vacuum in inch wc | 34.2 |

| Nominal capacity in m³/h @ Pa | 800 @ 7800 |

| Nominal capacity in cfm@inch wc | 471 @ 31.3 |

| Dimensions in mm (WxDxH) | 1430x790x2020 |

| Dimensions in inch (WxDxH) | 56.3x31.1x79.5 |

| Weight in kg | 350 |

| Weight in lbs | 772 |

| Noise level in dB | 65 |

| Connection variants – diameter in mm | 1 x 150 Jacob connector |

| Connection variants – diameter in inch | 1 x 5.9 Jacob connector |

System benefits

High flexibility

Many of the ULT fume extraction systems can be utilized flexibly. For example, you can choose between mobile or stationary systems, device integrations or special ventilation solutions. If necessary, the ideal application is configured by ULT experts on-site.

Modular system structure

Modularity is the basis for the effective use of ULT’s ventilation solutions. This lets you respond flexibly to changing contaminant or work scenarios and therefore always utilize the full potential of your systems.

Optimal filter technology

Using the most sensible filtration technology ensures a long filter service life and, consequently, reduces the costs of maintenance and spare parts. ULT always offers you the optimal solution for your special contaminant technology to achieve the best filtration possible.

Individual extraction solutions

Your extraction systems are adapted to your needs. Starting from the contaminant situation, via your internal processes, to the best possible collection solution, ULT advises and supports you in the selection and installation of your optimal extraction and filtration solution.

Individual extraction solution

Your systems will be adapted to your needs. Starting with the pollutant situation and your internal processes to the best possible collection solution - we advise and support you in the selection and installation of your ideal extraction and filtration solution.

High filter service life

The high priority of filter elements in ULT systems reduces medium and long-term costs for maintenance and materials. In addition, the periods of downtime for necessary filter changes or system cleaning are significantly reduced.

Possible applications and equipment

Operating principle and benefits of the LAS 800

Download operating instructions

You are welcome to download the operating instructions and documentations of your LAS 800 laser fume extractor by entering the serial number in the special download area. The documents contain information on the installation, operation and maintenance of your products.

Downloads

Images

We're happy to help you!

We are happy to offer you further information about our extraction systems and the respective filtration technology. We can also configure your individual solution as requested or required.