Soldering Fume Extraction for Industrial Use

Enhance Your Soldering Operations: Discover The Ultimate Fume Extraction Solutions

Why should your industry choose ULT for solder fume extraction?

In the dynamic world of industrial soldering, ensuring a clean, safe, and efficient work environment is not just an option—it's a necessity.

ULT's cutting-edge solder fume extractors offer unparalleled solutions to eliminate harmful solder smoke and fumes, fostering productivity and health. Our products cater to a broad spectrum of industries, making them the ideal choice for American, Canadian, and Mexican businesses seeking top-tier solder fume extraction technology.

Explore our range - Enhance your workspace now!

Efficiency redefined: the impact of advanced filtration

Why settle for less when you can have the best?

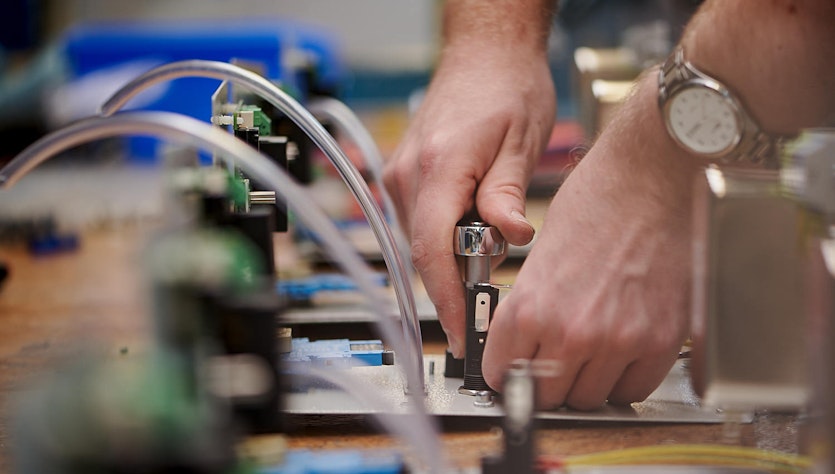

ULT's solder fume extractors are designed with sophistication and precision. Providing a carefully developed filtration technology, these systems capture and neutralize even the most microscopic particles and vapors emitted during soldering processes. This not only ensures compliance with stringent health and safety regulations but also significantly improves the air quality, leading to a healthier work environment and enhanced employee productivity.

Discover the difference - experience pure air!

Overview of devices for soldering fume removal

Flexible solution for mobile soldering fume extraction

JUMBO Filtertrolley LRA

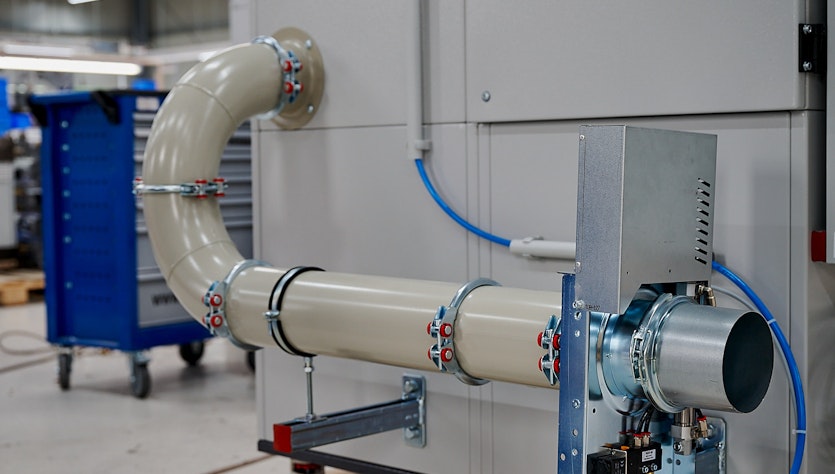

The solution developed for mobile utilization with a unique design is the JUMBO Filtertrolley LRA. The flexible soldering fume extractor can be variably adapted to a wide variety of workplace and air pollutant conditions.

The filter system is very quiet and yet powerful.

Technical approaches and case studies

Solutions for extracting soldering fumes and vapors

The best fit: our LRA series

Soldering fume and vapors pose risks to workers, equipment, and product quality. Extracting and filtering these airborne pollutants is crucial for workplace safety and efficient production. We offer customized solutions for capturing soldering fumes at the source, protecting employees and ensuring product integrity. Choose our extraction systems and filtration technology for optimal performance and safeguarding against harmful particles.

Our LRA series offers comprehensive solutions for extraction and filtration technology specifically designed for soldering fumes and vapors. Whether you have single-user workplaces or automated and partially automated manufacturing setups, our LRA series caters to all your requirements.

How does ULT's technology stand out in fume extraction?

Innovation at its core: leading the way with smart technology and filtration system

ULT's solder smoke absorber are not just machines; they are a testament to innovation. Featuring smart sensors and automated adjustments, they adapt to varying levels of fumes, ensuring optimal extraction without manual intervention. This level of automation reduces energy consumption and extends filter life, offering an eco-friendly solution without compromising performance.

Embrace Innovation - breathe easier with ULT!

Universal compatibility: a solution for every workspace

From compact soldering stations to extensive industrial setups, ULT's range of fume extractors seamlessly integrates into any workspace. Our versatile designs, including portable units and customizable installations, ensure that no matter the size or scale of your operation, there's a perfect fit. ULT's extractors are designed to work with a wide array of soldering equipment, providing flexibility and ensuring that every soldering job is covered by the best fume extraction technology available.

Find your perfect match - optimize your station now!

We're happy to help you!

We are happy to offer you further information about our extraction systems and the respective filtration technology. We can also configure your individual solution as requested or required.

Can ULT fume extractors enhance workplace safety and compliance?

Enhancing workplace safety and health in manufacturing companies: a focus on soldering fume control

Over recent decades, the significance of safeguarding both workforce well-being and health within manufacturing enterprises has witnessed a substantial rise. This trend is a natural progression, stemming from the escalating complexity of manufacturing procedures and the emergence of increasingly diverse and intricate contaminants. It is crucial to recognize that soldering fumes, for instance, encompass a variety of distinct fume types, each bearing its own unique characteristics.

Airborne pollutants present within soldering fumes yield detrimental effects on individuals, machinery, and finished goods alike. Notably, prolonged employee absenteeism may be attributed to health-related concerns. Simultaneously, the functionality of production equipment can be compromised, resulting in imprecise manufacturing due to the accumulation of contaminants.

Moreover, soldering fumes have the potential to taint or impair products, primarily due to the application of soldering fluxes. Such instances can lead to a decline in product quality, consequently tarnishing a manufacturing company's reputation and diminishing the demand for its offerings.

Efficiently extracting soldering fumes directly from their source holds paramount importance. This approach allows for the direct capture of the maximum concentration of contaminants. As extraction moves farther from the source, the effectiveness of pollutant removal diminishes, while the energy required for extraction increases. Hence, the extraction of soldering fumes necessitates positioning the capture mechanisms as proximate to the source of contamination as possible.

Find more on the importance of ideal emission capture

In the contemporary landscape, extraction systems and filtration technologies have evolved to encompass an extensive array of airborne pollutants. Specifically tailored to address soldering fumes, ULT delivers solutions tailored to diverse operational scenarios, encompassing both manual soldering stations and automated soldering systems.

Our focus lies in shielding your workforce, equipment, and merchandise from the adverse impacts of particles generated during soldering processes. We extend our support by providing extraction systems and filtration technologies meticulously calibrated to align seamlessly with your distinctive requisites. Elevate your workplace safety and uphold manufacturing excellence through our comprehensive solutions.

Why is ULT's after-sales support unmatched?

Commitment beyond sale: ensuring your continuous satisfaction.

At ULT, we believe our relationship with customers extends far beyond the initial purchase. Our comprehensive after-sales support, including maintenance, filter replacements, and technical assistance, ensures your fume extraction systems operate at peak efficiency throughout their lifecycle. With ULT, you're not just buying a product; you're gaining a partner dedicated to your success and satisfaction.

Join our family - experience support like no other!

The perfect soldering fume extraction unit

Advanced filtration technology: ULT's solder fume extractors utilize HEPA and special pre-filters for maximum efficiency.

Smart automated systems: our extractors adjust to fume levels automatically, enhancing performance and energy efficiency.

Versatility and compatibility: designed for every type of soldering station, ensuring a clean, safe work environment.

Enhanced safety and compliance: protect your workforce and comply with regulations effortlessly.

Unmatched sfter-sales support: comprehensive services for continuous operation and satisfaction.

Elevate your soldering standards with ULT's superior fume extraction solutions. Don't let solder fumes hinder your productivity or compromise your health. Explore our range, and let's make your workspace safer, cleaner, and more efficient.