ASD 300 Ex – Extraction System For Explosible Atmospheres

Product Details

Applications Fields

Removal of combustible dusts of explosion category St.1

Grinding, engraving, polishing

Cleaning, abrading, transfilling, etc.

Features

Stationary extraction unit with 15 l hobbock

Fully automatic filter cleaning via compressed air multi-jet nozzle

Powder coated, robust steel housing

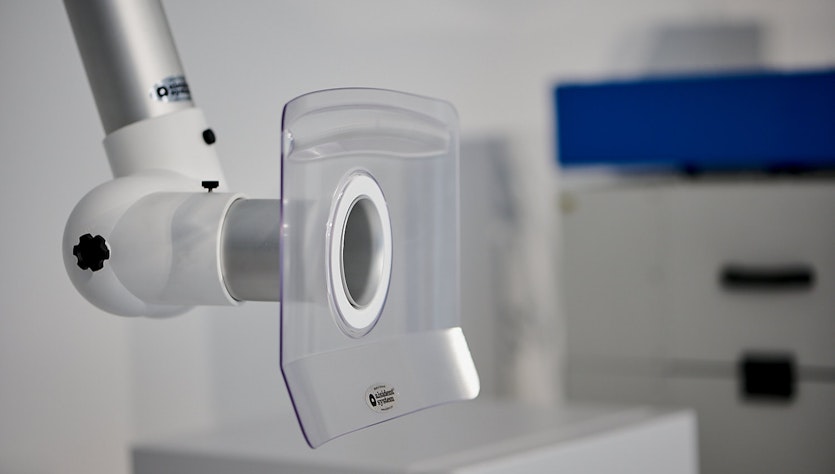

Connection of extraction arms 2 X DN 50

Equipment

Volume flow control: stepless adjustment of suction capacity

Loaded particle filter indicator: optical signalling

Use of polyester fleece filter cartridges with PTFE membrane, electrically conductive

Category C/BIA, safety post-filter HEPA H13 with aluminum separators

Technical specifications

| Device version | ASD 300 Ex EC | ASD 300 Ex FQ |

|---|---|---|

| Max. flow rate in m³/h | 220 | 450 |

| Max. flow rate in cfm | 129.5 | 265 |

| Max. vacuum in Pa | 22800 | 2600 |

| Max. vacuum in inch wc | 91.7 | 10.4 |

| Nominal capacity in m³/h @ Pa | 180 @ 6000 | 200 @ 2000 |

| Nominal capacity in cfm@inch wc | 106 @ 24.1 | 118 @ 8 |

| Dimensions in mm (WxDxH) | 370x590x1810 | 430x550x1340 |

| Dimensions in inch (WxDxH) | 14.6x23.2x71.3 | 14.6x23.2x71.3 |

| Weight in kg | 60 | 60 |

| Weight in lbs | 132 | 132 |

| Noise level in dB | 52 | 54 |

| Connection variants – diameter in mm | 2 x 75 | 2 X 75 |

| Connection variants – diameter in inch | 2 x 2.95 | 2 x 2.95 |

System benefits

Easy servicing

ULT’s extraction and filtration systems are designed so that they can be put into operation without problems and easily used. Should there be any questions, our service technicians would be happy to assist you at any time.

Individual extraction solution

Your systems will be adapted to your needs. Starting with the pollutant situation and your internal processes to the best possible collection solution - we advise and support you in the selection and installation of your ideal extraction and filtration solution.

R&D basis

Research and Development (R&D) has a very high priority at ULT. Several projects with prestigious partners and institutes have produced new approaches to ventilation systems that often become series products or are adapted quickly and easily to customer-specific projects.

Optimal filter technology

Using the most sensible filtration technology ensures a long filter service life and, consequently, reduces the costs of maintenance and spare parts. ULT always offers you the optimal solution for your special contaminant technology to achieve the best filtration possible.

Quiet operation

ULT’s extraction and filtration systems are especially quiet. This is appreciated by numerous clients worldwide. This means your employees won’t be bothered by unnecessary noise.

Modular system structure

Modularity is the basis for the effective use of ULT’s ventilation solutions. This lets you respond flexibly to changing contaminant or work scenarios and therefore always utilize the full potential of your systems.

Image

Your contact at ULT