Supporting Various Process Steps In Battery Cell Production

Support of Various Process Stages of Battery Cell Production

ULT offers overall ventilation system solutions along the value-added process for battery production through to their disposal. The following process steps are primarily supported:

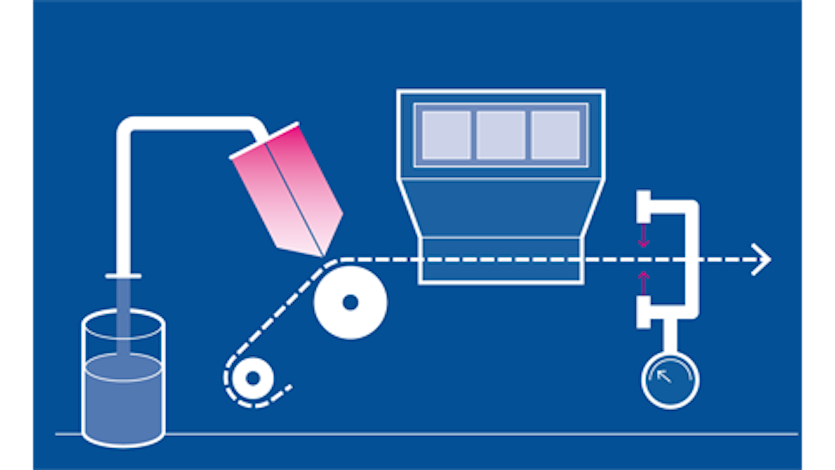

Coating processes anode/cathode

Typical processes in this manufacturing step are:

Powder handling

Mixing

Coating

Calendering

Drying

ULT offers fume collection and extraction solutions as well as conceptual air drying technology along the material mixing and coating process.

Coating process in battery production

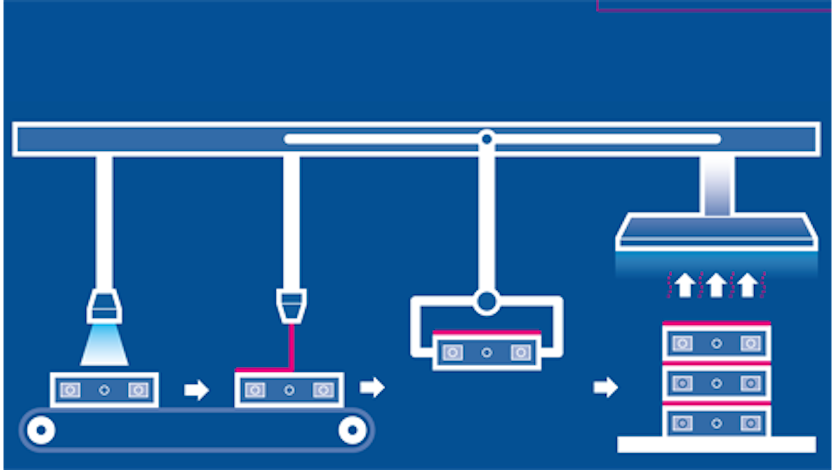

Battery cell production

Typical operations at this stage of the process include::

Cutting

Stacking

Welding

Packing

Separating

Filling

ULT offers complete ventilation system solutions for this battery cell manufacturing process.

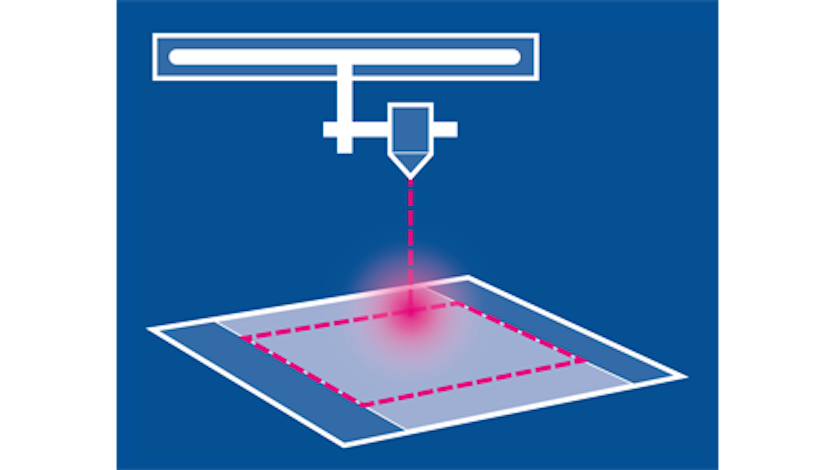

Process step separating

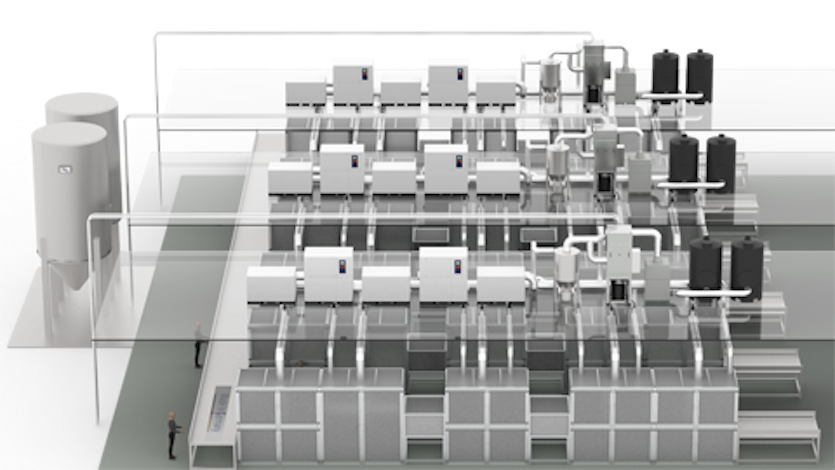

Use of mini environments

A unique solution: ULT develops solutions for air drying in relation to so-called "mini environments". This concept has significant advantages in terms of energy savings (up to 77%) for companies and clean working conditions for personnel. Through energy-optimized processes, battery manufacturers can not only save money, but also significantly increase productivity.

In these "mini-environments", the production machine for battery cell manufacturing is enclosed and its air is dehumidified to the necessary level between -4°F (-20°C) and -76°F (-60°C) dew point temperature. In addition, contaminated air is collected and filtered at the respective laser cutting and laser welding units. ULT masters the necessary air balance management.

In this area, ULT supports users from conceptual consulting and system design to installation and commissioning of the entire system technology.

Mini environments in the battery cell production

Battery production

Battery manufacturing processes are diverse. Typical steps along the battery manufacturing process that require air drying, exhaust and filtration solutions are:

Cleaning and bonding

Contacting of battery cells

Assembly and welding

Separation and joining processes or surface structuring by means of lasers or similar processes are used. processes are used. ULT offers a wide range of consulting and product solutions for this.

Preassembly of the cell modules

Disposal

The disposal of batteries produces a wide variety of toxic pollutants, many of which are harmful to health. ULT offers a broad portfolio of consulting and product solutions for air pollution control and thus occupational health and safety.